Precision Welding Automation for Heat Exchangers

Achieve flawless tube-to-tubesheet welding with our customized automation systems. Engineered for accuracy, consistency, and efficiency, our Heat Exchanger Welding Solutions help manufacturers streamline production, reduce maintenance costs, and guarantee long-term reliability across demanding industrial applications.Contact Now!

Advanced Heat Exchanger Welding Systems

Advanced Heat Exchanger Welding Systems

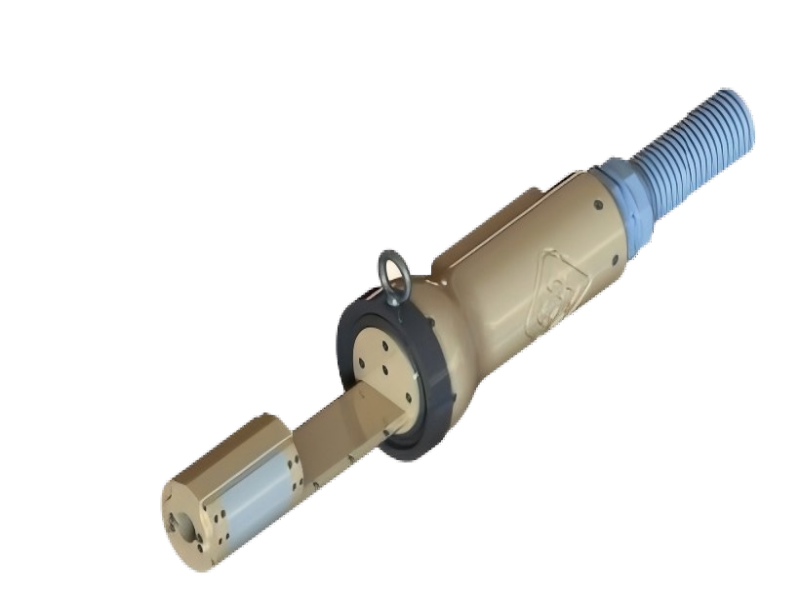

MWH-21A Heat Exchanger Welding Solutions

MWH-25A Heat Exchanger Welding Solutions

MWH-16A Heat Exchanger Welding Solutions

Ready to Automate Your Heat Exchanger Welding?

Key Features of Our Welding Systems

Built for precision, consistency, and performance — our heat exchanger welding solutions combine advanced technology with industry expertise to deliver flawless welds and reliable results in every production cycle.

Precision Control System

Adaptive motion and weld parameter control ensure smooth, repeatable joints even on complex tube-to-tubesheet configurations.

Real-Time Quality Monitoring

Integrated sensors and software provide live feedback on weld quality, minimizing defects and rework.

High Productivity & Flexibility

Rapid cycle times and modular configurations adapt seamlessly to different exchanger sizes and materials—maximizing output and ROI.

Key Features of Our Welding Systems

Built for precision, consistency, and performance — our heat exchanger welding solutions combine advanced technology with industry expertise to deliver flawless welds and reliable results in every production cycle.

Precision Control System

Real-Time Quality Monitoring

High Productivity & Flexibility

Wide Applications Across Heat Exchanger Manufacturing Industries

Designed for heat exchanger manufacturers in HVAC, power generation, petrochemical, and marine industries. Our automated welding systems deliver consistent, high‑precision tube‑to‑tubesheet joints, meeting ASME and TEMA standards. They ensure efficiency, reduce labor costs, and guarantee long‑term reliability across demanding production environments—ideal for both large‑scale fabrication and specialized custom projects requiring superior weld quality and traceability.

Leading Provider of Orbital Welding Solutions

We specialize in developing and manufacturing advanced orbital welding systems, focusing on serving high – purity industries such as pharmaceuticals, food processing, and heat exchanger manufacturing. Driven by innovation, strict quality control, and customer – centric service, we deliver reliable and efficient welding solutions that optimize production and meet stringent industry standards.

What Our Clients Say

Hear from global manufacturers who have enhanced their heat exchanger welding quality and productivity with our automated solutions. Their success stories demonstrate how our technology ensures consistent precision, faster cycles, and unmatched reliability across demanding heat exchanger and pressure vessel applications.

Collaborate with Us for Advanced Welding Solutions

We offer diverse collaboration models to help businesses integrate cutting - edge orbital welding technology (including our MWH series for heat exchangers) into their operations. Whether you’re a manufacturer, distributor, or in need of customized solutions, we’re committed to working together for mutual success.

01

02

03

Frequently asked questions

Yes. We design and manufacture systems tailored to your specific tube dimensions, materials (such as stainless steel, titanium, copper, or carbon steel), and production requirements. Each solution is engineered for maximum compatibility and performance.

Standard models are typically available within 4–6 weeks, while customized systems may require 8–10 weeks, depending on complexity. Our production team ensures timely delivery through efficient project management and quality control.